Watch or Read?

Would you like to explore this example through a short video or text? If you prefer the video, check out the preview on the right (or below if you’re on a mobile device).

The video includes animated explanations and additional examples, such as graphing derivatives and other useful visualizations.

Prefer text? Just keep reading!

Introduction

In math class, derivatives are often used to analyze functions—determining where they increase, decrease, or have critical points. These properties make derivatives valuable for solving real-world optimization problems.

What Is Optimization?

In industry, optimization is the process of designing systems to achieve maximum efficiency while minimizing waste. This includes reducing material use, cutting energy consumption, and lowering costs without compromising quality.

Examples of optimization tasks:

- Packaging: Designing cans to use the least metal while maintaining the same volume.

- Transport: Streamlining vehicle shapes to maximize fuel efficiency.

- Energy: Shaping wind turbine blades to capture the most power with minimal material.

- Construction: Designing the strongest bridges with the least amount of steel.

Derivatives in Optimization

Derivatives help identify critical points, making them essential for optimization. They pinpoint where a system reaches its optimal state—whether it’s minimizing material, maximizing efficiency, or balancing costs.

Let’s look at a specific example: designing a cylindrical steel container (a can).

Use Case: Finding the optimal shape for a steel can

Problem Statement

Consider a paint can. When manufacturers design these containers, they aim to reduce material use—in this case, minimizing the can’s surface area.

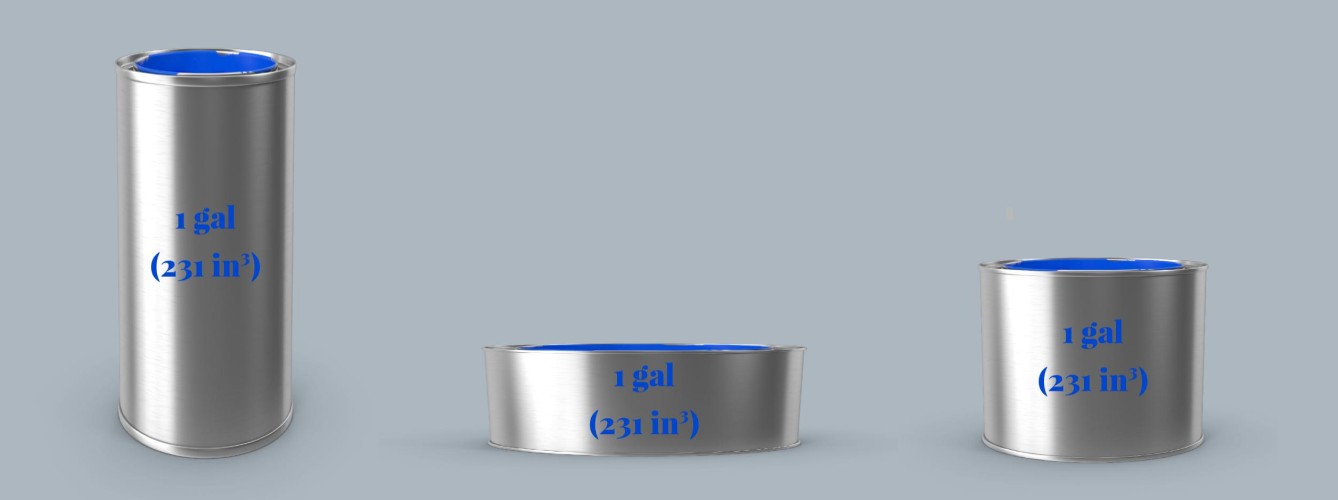

The shape of a can can vary, as shown below:

For a 1-gallon (231 in³) can, the shape could be tall and skinny, short and wide, or somewhere in between.

But which shape uses the least material? Derivatives can help us determine the optimal design.

Step 1: Calculating Total Surface Area

To start, we need a function that represents the total surface area of a can, including the top, bottom, and sides:

\[ S = \pi r^2 + \pi r^2 + 2\pi r h = 2\pi r^2 + 2\pi r h \]

Step 2: Expressing One Variable in Terms of Another

This equation contains two variables: r (radius) and h (height). Since the volume is fixed at 1 gallon, we can express h in terms of r using the volume formula:

\[ V = \pi r^2 h \Rightarrow h = \frac{V}{\pi r^2} = \frac{231}{\pi r^2} \]

Step 3: Substituting into the Surface Area Formula

Replacing h in the surface area formula gives us a function of a single variable r:

\[ S(r) = 2\pi r^2 + 2\pi r \left( \frac{231}{\pi r^2} \right) = 2\pi r^2 + \frac{462}{r} \]

This function describes how surface area depends on r, allowing us to differentiate it.

Step 4: Taking the Derivative

To find the critical point—where the surface area is minimized—we take the derivative:

\[ S'(r) = 4\pi r – \frac{462}{r^2} \]

Setting the derivative equal to zero:

\[ 4\pi r – \frac{462}{r^2} = 0 \]

Solving for r:

\[ r \approx 3.325 \text{ inches} \]

This is the optimal radius that minimizes the material used for a 1-gallon can.

Step 5: Calculating Optimal Height

Substituting r ≈ 3.325 inches back into the height equation:

\[ h = \frac{231}{\pi r^2} \approx 6.65 \text{ inches} \]

Notice that the height is twice the radius. This is the ideal proportion for a cylindrical can that minimizes material use.

Real-World Considerations

The ideal proportions we calculated work well from a material efficiency standpoint. However, real-world design also considers practical factors:

- Soda cans aren’t designed with the exact optimal ratio because a can with equal diameter and height would be awkward to hold.

- Paint cans, however, are often designed close to this ideal shape, reducing material and energy use in manufacturing.

This demonstrates how derivatives help engineers balance efficiency with real-world usability.